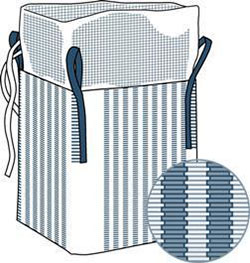

These Bags are specially designed to store food items that require to breath, like potatoes, onions etc. The ventilated fabric permits the required air flow through the fabric into the bag, thus preventing spoilage due to moisture and mold build-up. These Bags are specially designed to store food items that require to breath, like potatoes, onions etc. The ventilated fabric permits the required air flow through the fabric into the bag, thus preventing spoilage due to moisture and mold build-up.

Usage of FIBC Ventillated Bags have eased the common supply chain issues of handling, storing and transporting food items, commonly witnessed with the 25/50 kg woven sack bags.

Available Options Available Options

• Coated or Uncoated fabric

• Safe Working Load Range 500 Kg to 2000 Kg

• Generally have a safety factor of either 5:1 (single

trip) or 6:1 (multi trip)

• Tubular or Shaped Liner

• Multicolour printing options on 4 sides or 2 sides

• Pouch for Documents and Labels

As with all FIBC’s bags in Ventilated Bags there are many other options for Loops, Top Filling and Bottom Discharge.

We can Customize and Design any form of FIBC that may be relevant to your particular Product or Industry.

Different Loops are:

|

|

|

|

| Corner Loop / Side Seam Loop |

Cross Corner Loop |

Tunnel / Sleeve Lift Loop |

Hood Lift Bag / Two Lifting Strap / Loop |

| |

|

|

|

|

|

|

|

| Ancillary Loop |

Single Stevedore Strap / Loop |

Double Stevedore Strap / Loop |

|

Optional Features for TOP Filling and Closure:

|

|

|

| Open Top with Hem |

Tie-Down Flap |

Duffle Top |

| |

|

|

|

|

|

| Open Top & Tightening Holes |

Open Top with Draw Cord |

Filling Spout |

Optional Feature for Bottom Discharge:

|

|

|

|

| Discharge Spout |

Discharge Spout with Iris Protection |

Discharge Spout with Petal Closure |

Discharge Spout with Sewn Cover |

| |

|

|

|

|

|

|

|

| Discharge Spout with Protection Flap |

Full Drop Bottom |

Double Stevedore Strap Bag Quick Discharge / Conical Base |

|

Different Style and Type of Liners

The Liners produced from Co-Ex, PP, or MC materials - clear or colored

|